Oil, grease, penetrating oil, dry lubricants – there are so many different types and brands of automotive and shop lubricants that it can be hard to know which one to use in a specific situation. Often, shop and automotive lubricants are suited to very specific purposes. For example, the penetrating oil WD-40 is not, contrary to popular belief, meant to be sprayed on everything.

And it’s important that you use the right lubricant when you’re greasing (or oiling) something up. Speciality lubricants formulated for specific uses last longer and work better than lubricants designed for general purposes or for another kind of job. Here are the different kinds of shop and automotive lubricants, what they’re used for, and how to use them.

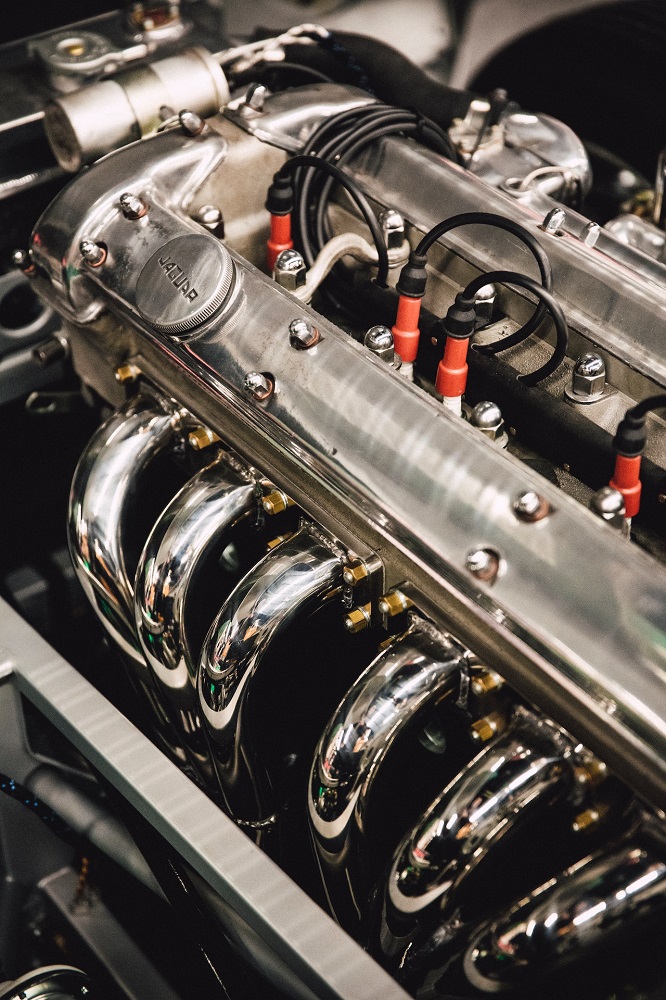

Oils

Oils are fluid lubricants made up of polymer chains that are hard to break – this chemical structure allows oils to create slip between two surfaces. When shopping for oil lubricants, make sure you get the right weight. Weight indicates viscosity, with lower numbers corresponding to thinner oils.

Lubricating oils include things like sewing machine oil, motor oil, bar and chain oil, and 3-in-1 oil. It’s used to oil bearings and hinges, lubricate tools, and sharpen blades. Unlike greases, oils don’t provide any resistance to cushion parts, but they are good for getting lubrication into cracks, crevices, and crannies without the hassle of taking something apart. Don’t use oils in situations where dirt, dust, and grime are likely to get onto or into the thing being lubricated. Grime will stick to the oil and could gum things up. Oils are not a good choice to lubricate surfaces that are exposed to moisture and humidity, as they can’t lock moisture out effectively. Because they’re so thin, oils can also drip and run, so there is a staining risk when you use them.

Greases

Greases come in a range of viscosities, starting at about the thickness of ketchup and ending up as thick as cheese. Greases offer some cushioning for parts, so they’re best used in situations where the components being lubed are under a lot of pressure or see high use. Grease stays where it’s put, instead of dripping away like oil, so it’s great for lubricating bearings, axles, and other parts that need some cushioning. One of the most useful properties of grease is a quality known as shear thinning, which means that the more pressure is placed on the grease, the less viscose it becomes. That means it’s thick and sticky and stays in one place, but can also create plenty of slip between two surfaces.

However, not all greases are suitable for all jobs. White lithium grease is appropriate for general purpose, light- to medium-load jobs – think lubricating tools or garden equipment. Marine grease is appropriate for heavy-duty moisture protection in environments where components are exposed to water and humidity constantly – it will lock out moisture and prevent seizing. Synthetic grease is intended to stand up to high use and lots of pressure – it’s perfect for axles, gears, and bearings.

Dry Lubricants

Dry lubricants are appropriate for situations in which you need to lubricate tiny components in mechanisms that can’t get gunked up by grease or oils. Think locks, hinges, and 3D printer rails. Dry lubricants are made out of silicone, graphite powder, molybdenum disulfide, or polytetrafluoroethylene (PTFE). These lubricants are typically mixed in an aerosol can with a solvent. Once you spray these lubes, the solvent evaporates, leaving behind a dry chemical film that creates slip between the surfaces without attracting dust and grime. PTFE lubricants work by bonding with the surface, be it wood, metal, plastic, or rubber. Silicone and graphite lubricants leave behind a film that lets surfaces slide smoothly against one another, but silicone can attract dust and dirt. Use a dry silicone lubricant if dust is a concern, or go with a graphite powder lubricant.

Penetrating Lubricants

Penetrating lubricants, like WD-40, are meant for getting into the cracks and crevices between surfaces and breaking up rust to loosen seized connections. You can use penetrating oil to free rusted bolts, corroded bushings, and other things that are stuck and seized up with rust. However, these thin oils aren’t appropriate for most general lubrication tasks. Choose something else if you want to keep something slippery long-term, as opposed to just adding some slip in the moment.

There are so many shop and automotive lubricants out there, it can be easy to get confused. Be careful about using the right lubricant for the right job, so you can keep your hinges, bearings, and axles in good working order for years to come.

Featured post

© Copyright 2022 Antonia, All rights Reserved. Written For: Tidylife

Leave a Reply